en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

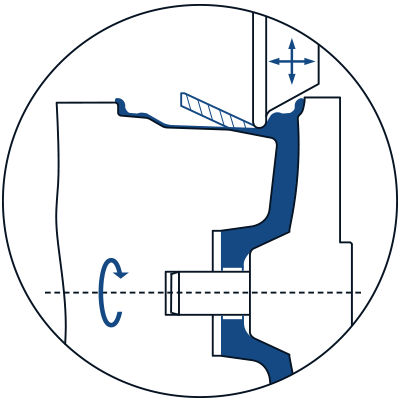

The fundamental principle of groove spinning forming lies in the transfer of metal volume, adhering to the principle of volume invariance in plastic deformation. Essentially, groove forming is achieved through material flow along the tube wall, which results in variations in wall thickness. This change in thickness is a characteristic of flow forming. However, unlike conventional flow forming, where the material predominantly flows axially, groove spinning forming also induces a radial material flow due to the applied pressure.

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

CNC Wheel Rim Spinning Machine, meticulously crafted for the precision forming of casted or forged hub wheels through spinning. This cutting-edge equipment employs a symmetrical dual-wheel spinning mechanism, allowing for the configuration ......