en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

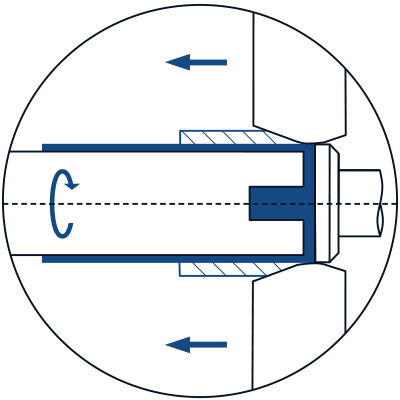

Multi-Rollers technology: cylindrical deformation thinning spinning is a process for manufacturing thin-walled, elongated cylindrical components. This method involves spinning rollers pressing against a tube blank. The tube blank rotates in sync with the mandrel and moves along its axis. This spinning technique adheres to the principle of constant metal volume. Depending on the movement direction, it can be categorized into two types of spinning: forward spinning, where the material flow direction aligns with the roller, and reverse spinning, where the material flow is opposite to the roller's direction.

Regarding the deformation mechanism and part shapes, strong spinning is classified into two types: cylindrical part spinning (flow spinning) and conical part spinning (shear spinning). Flow spinning is primarily used for creating high-precision, elongated cylindrical components. In contrast, shear spinning is more suited for shaping conical components.

This version aims to maintain the original technical details while improving readability and clarity.

Our most advanced and versatile model can handle both ducts and plates up to 25mm thick, making it perfect for producing parts for both axial and centrifugal fans. Our machine is capable of handling various parts such as fan casing, impelle......

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

Three rollers spinning machine are mainly used for the spinning of the reducing or thickening of the tubes; Small diameter of the thick materials and could harden some surface by spinning The machine has the advantages of high rigidity and ......

CNC Hot spinning machine featuring Siemens CNC, automatic lubrication and heating system is specially designed for high pressure cylinders (lpg, fire extinguishers & gas etc), pressure vessels, and nd closing & neck forming of high pressure......

CNC Wheel Rim Spinning Machine, meticulously crafted for the precision forming of casted or forged hub wheels through spinning. This cutting-edge equipment employs a symmetrical dual-wheel spinning mechanism, allowing for the configuration ......